Ptfe Thread Seal, Ptfe Thread Sealant Tape

Plumb Pack" Brand PTFE Thread seal Tape is an ideal seal material. The PTFE Threaded Tape are manufactured according to International Standards & Specifications. All the manufacturing processes arecontrolled as per the ISO 9001:2000 Quality Control Systems. The "Plumb Pack" Tm Brand PTFE tapes are confirmed to American UL and Japanese JIS standard.

The technical details of the "Plumb Pack" tape are as below :

Salient Features :

- Low Coefficient of Friction

- Excellent Chemical & Corrosion Resistance

- Non Surface Sticking, Non Contaminating, Non Hardening

- Wide Working Temperature Range - 190C to +370 C

- High Pressure Resistance - 150 - 200 Kg/Sq Cm

- Tensile Strength > *N/sq mm

- Ultimate Elongation > 25%

Specifications :

Sizes |

Tolerance | |||

| Width | 12.5mm | 19 mm | 25mm | + 0.5 mm |

| Length | 12 mts | 12 mts | 12 mts | + 0.5 mt |

| Thickness | 0.1 mm | 0.1 mm | 0.1 mm | + 0.01 mm |

| Apparent Density | 0.5 gm/cc | 0.5 gm/cc | 0.5 gm/cc | |

Packing :

Shipping Carton - 10 x 100 Pcs

Competitive Advantage :

- Assured Quality confirming to UL & JIS International Standards

- Competitive Prices

- Prompt & Reliable Service

Ptfe Thread Seal

PTFE Thread Sealant Tape, due to the special nature of the thread seal will be lasting and resistant to high temperatures and corrosive chemicals. The seal will not harden or become brittle but will remain flexible enough when the seal is opened for maintenance.

PTFE Thread Sealant Tape, due to the special nature of the thread seal will be lasting and resistant to high temperatures and corrosive chemicals. The seal will not harden or become brittle but will remain flexible enough when the seal is opened for maintenance.

PTFE Thread Seal abt Tape can be used for various media from corrosive chemicals to water and gas to oil, in hydraulics and pneumatics.

Instructions for Proper Usage

Wind the tape by hand, using a constant minimal tension sufficient for the tape to take up the form of the thread.

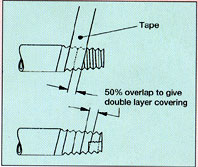

The tape should be wound in a helical fashion with a 50% overlap (as shown in diagram) in the direction of the thread so that when the connection is completed the finishing end of the tape remains in position. The tape width should not exceed the length of the thread form.

Ptfe Expanded Joint Sealent Tape

Expanded PTFE Joint Sealant is made from 100% white pure virgin imported PTFE resin combined with a continuous self-adhesive strip for easy application. Plus its main characteristics of excellent flexibility, good resistant to crep and cold flow, it also resists high & low temperature, corrosion and aging, and can be lubricated by itself. It has the properties of Air-tight, water-proof under the pre-tight pressure. Its sealing property is remarkable, installation is extremely convenient,and can cut along with usage.so it is the ideal packing material in the industry field of chemical, the medicine, petrified, food drink, the electron, the electric power, the metallurgy, the ships.

Expanded PTFE Joint Sealant is made from 100% white pure virgin imported PTFE resin combined with a continuous self-adhesive strip for easy application. Plus its main characteristics of excellent flexibility, good resistant to crep and cold flow, it also resists high & low temperature, corrosion and aging, and can be lubricated by itself. It has the properties of Air-tight, water-proof under the pre-tight pressure. Its sealing property is remarkable, installation is extremely convenient,and can cut along with usage.so it is the ideal packing material in the industry field of chemical, the medicine, petrified, food drink, the electron, the electric power, the metallurgy, the ships.

Usage:

All kinds of flange surface in enamel lining, the glass lining, the plastic lining, the rubber lining, the graphite lining and the titanium steel tower, the heat interchanger. The ventilation duct, the concrete lid, FRP, compress rack, hydraulic & pneumatic system ,water system. All kinds of pipeline flange surface seal. Special for flange of which Face work precision is bad, un- smobth region is big, the shape is irregular. The environment in strong corrosive medium and slightly pollute.

Expanded PTFE Joint Sealant is made from 100% pure PTFE. It has excellent functions of anti-acid & anti-alkalis and well tensile strength recovery. It is especially used in food, drink, chemical etc. It can be used easily without making gasket

| STANSERS SIZE | |||

| 3.0MM(T)*1.5MM(W)*30M(L) | 19MM(T)*3.0MM(W)*5M(L) | ||

3.0MM(T)*2.0MM(W)*30M(L) |

17MM(T)*3.0MM(W)*5M(L) | ||

| 4.0MM(T)*2.0MM(W)*20M(L) | 17MM(T)*6.0MM(W)*5M(L) | ||

| 5.0MM(T)*2.0MM(W)*20M(L) | 20MM(T)*3.0MM(W)*5M(L) | ||

| 5 .OMM(T)*2.5MM(W)*20M(L) | 20MM(T)*5.0MM(W)*5M(L) | ||

| 5.0MM(T)*3.0MM(W)*20M(L) | 20MM(T)*7.0MM(W)*5M(L) | ||

| 6.0MM(T)*2.0MM(W)*25M(L) | 25MM(T)*3 OMM(W)*5M(L) | ||

| 6.0MM(T)*3.0MM(W)*15M(L) | 25MM(T)*5.0MM(W)*5M(L) | ||

| 7.0MM(T)*2.0MM(W)*15M(L) | 25MM(T)*1~MM(W)*5M(L) | ||

| 7.0MM(T)*3.0MM(W)*15M(L) | 30MM(T)*3.0MM(W)*5M(L) | ||

| 8.0MM(T)*3 .OMM(W)* 15M(L) | 30MM(T)*4.QMM(W)*5M(L) | ||

| 8.0MM(T)*3.5MM(W)* 15M(L) | 30MM(T)*5.0MM(W)*5M(L) | ||

| 9 .OMM(T)*3 .OMM(W)* 15M(L) | 35MM(T)*3.0MM(W)*5M(L) | ||

| 9.0MM(T)*4.0MM(W)*10M(L) | 35MM(T)*4,OMM(W)*5M(L) | ||

| 10MM(T)*3.0MM(W)*10M(L) | 40MM(T)*3.CMM(W)*5M(L) | ||

| 10MM(T)*3.5MM(W)*10M(L) | 40MM(T)*5.0MM(W)*5M(L) | ||

| 10MM(T)*4.0MM(W)*10M(L) | 45MM(T)*3.0MM(W)*5M(L) | ||

| 12MM(T)*4.0MM(W)*8M(L) | 50MM(T)*3.0MM(VV)*5M(L) | ||

| 14MM(T)*3 .OMM(W)* 1 OM(L) | 50MM(T)*5.0MM(W)*5M(L) | ||

| 14MM(T)*5.0MM(W)*5M(L) | |||

| 15MM(T)*3.0MM(W)*5M(L) |

| MAIN PROPERTIES | ||

| Items | Unit | Propert Value |

| Density | g/cm3 | 0.75 |

| Tensile Strength | Mpa | > 8.0 |

| Volatility | % | <1.0 |

| Hardness | HA | 30-70 |

| Creep Relaxation | % | <40 |

| Applicable Temperatures | -100-280 | |

| Applicable Pressure | Mpa | gas :6 Liquid 6.4 |

| RH RANGE | 0-14 | |

| Bolting Pressure | Mpa | Min8-20(3mm-25mm) |

| Moisture Content | % | <0.01 |

| Molting Point | 327 | |

| Hot Usability | index | 10 |

| Average Granule Diameter | ~m | 500 |

| Hot Usability |